|

|

|

what's news what's news |

|

| |

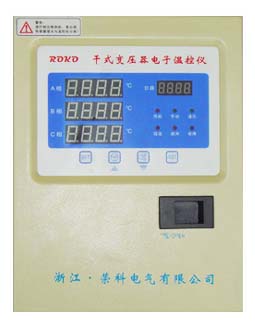

| Electronic thermo-controllers |

|

Product General

BWDK-5000 thermo-controllers for dry-type transformer series, idesigned and manufactured by standards of < electronic thermo-controller for transformer> JB/T7631-2005, is a new generation of Intelligent Instrumentation for ensuing the safe operation of dry-type transformers.

Controller use three (or four)ф3 the Pt100 platinum resistance as temperature sensor, embedded platinum resistance within the low-voltage winding by the transformer factory. It results in platinum resistance synchronous changes when transformer winding temperature increase, the thermo-controllers will show the three-phase winding temperature (room temperature or cores) on same screen for different platinum-resistance after dealed with by computer itself, meanwhile completed various alarm, control and signal output.

Controller send temperature data and parameters to the remote computer to form Distributed Control System through the analog output or RS232C. RS485 communications, the thermo-control device with communications function match control software of the Windows version for the convenience of user. |

|

| Electronic thermo-controllers |

|

|

| |

Main Features

-

Compact structure, nice appearance and easy installation. User is able to repair or replace the controller without break the electricity.

-

Show four temperatures on same screen: three-phase winding temperature and room temperature (or cores), displayed intuitively and clearly by different color LED.

-

With the black box function, record the previous temperature of transformer at the power OFF and the highest temperature.

-

Regularly on and off function of fan and alarm function when transformer Cupboard Door Open.

-

New anti-jamming de sign and meet national standards for electromagnetic compatibility requirements of the various indicators.

|

| |

| Technical parameters |

| Using environmental temperature |

-20~55℃ |

| Relative humidity |

≤90%(25℃) |

| Working Power |

AC220V±10% |

| Value figures show that the temperature compensation |

0~±20.0℃ |

| Alarm Contact |

7A / 250V AC |

| POWER consumption |

8W |

| OPENING size |

230+1×180+1mm (H × W) |

| measure scope |

0.0~200.0℃ |

| distinguish CAPBILITY |

0.1℃ |

| Precision |

0.5 |

| Fans contact |

16A / 250V AC |

| Sensors |

φ3 Platinum Resistance |

| Dimensions |

260×200×70mm(H × W × T) |

|

|

| |

| Model Note |

| Model |

Basic functions |

Additional features |

communication |

| BWDK-5000□ |

three-phase winding temperature show on same screen, Over-temperature alarm and output, Tripping over-temperature and output, Failure Alarm, Manual / automatic fan control , Alarm when Transformer Cupboard Door Open,Value figures show that the temperature compensation, "Black box" function,Output function tests. |

NULL |

The model code suffix "□" said communication for temperature control instrument and PC, Stated the following: Suffix omission means no communication; "S" is expressed as RS485 serial communication; "R" is expressed as RS232C serial communication; "A" means three analog current (or voltage) signals which corresponded by output Temperature Controller and winding temperature. |

| BWDK-5001□ |

room temperature monitoring |

| BWDK-5002□ |

Core temperature Detection and Alarm |

|

| |

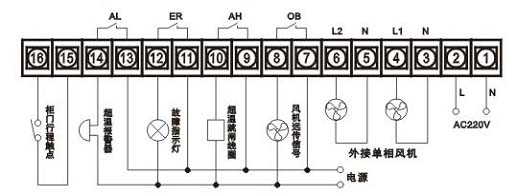

| Internal wiring |

|

| |

| Installation steps |

- Sensors will be the end of the platinum resistance were buried transformer A, B, C and within the three-phase low voltage winding properly fixed sensor cable.

- Open the door for temperature control, the sensor will plug cables, plugs and other communications cables through the line of control after the shell-temperature control under the threads in the hole for the introduction of temperature control, and as shown on the fixed sensor plugs, communications plugs and other connection The Line of Control.

- Check wiring correct, open the instrument power switch, start a normal temperature for the work.

|

| Size and installation |

Inlay-mounted installation : The transformer box or box-type substation installed by Shell on the embedded processing-size (181 × 231mm) and four fixed-prestressed (position 100 × 242mm).

Fixator installation : With the M12 screw fixation followed by the installation of vertical hole will fixator transformer installed in the angle bracket. |

| |

|

|

|

|